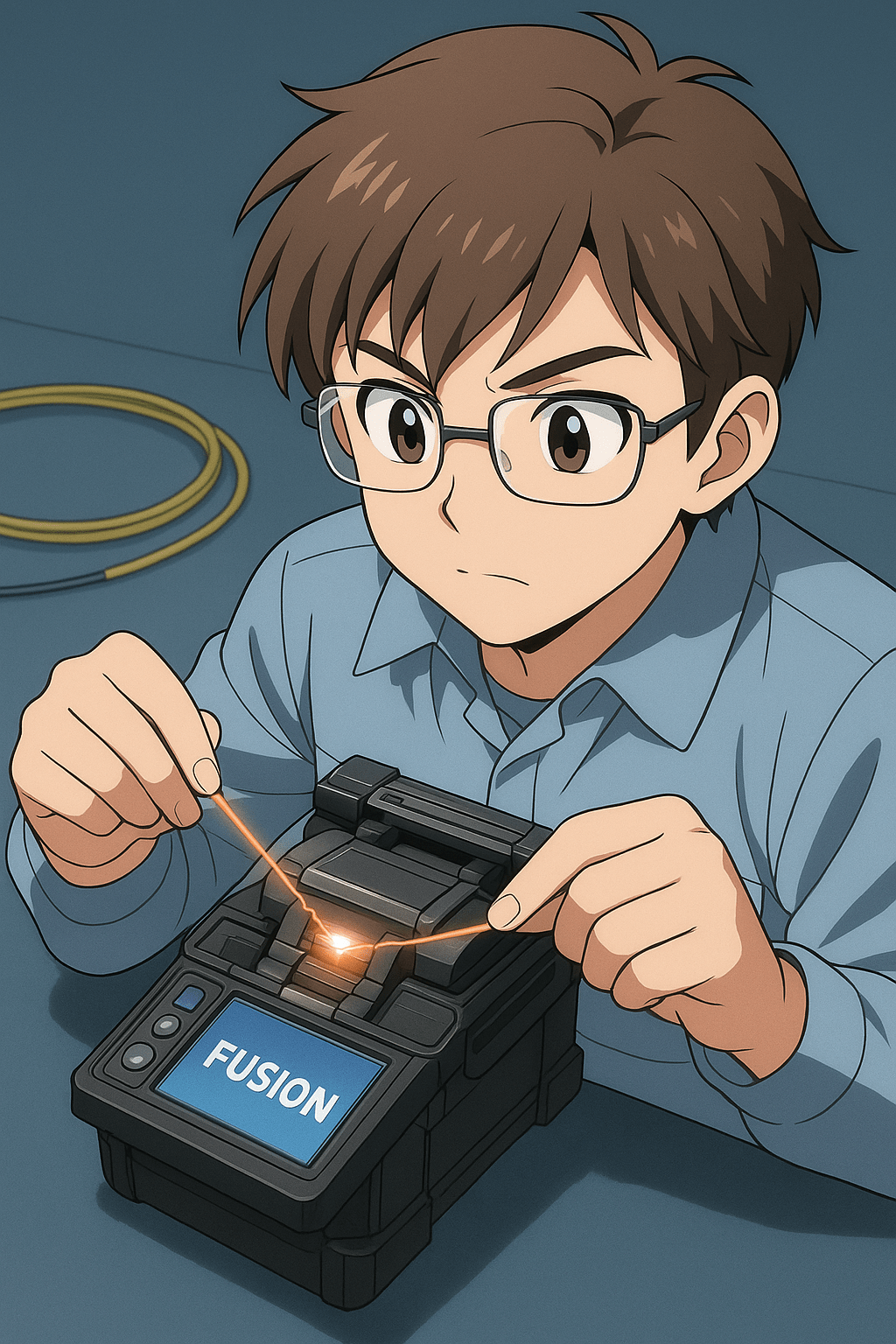

Fusion splicing is the process of permanently joining two optical fibers end-to-end by fusing them together using an electric arc. The goal is to align the fiber cores precisely and create a continuous optical path that minimizes signal loss and reflection. When properly done, the joint is almost as strong as the original fiber and provides extremely low attenuation (typically less than 0.1 dB).

The process involves several key steps:

- Stripping: Removing the protective coating from the fiber ends.

- Cleaning: Using isopropyl alcohol to remove dust or debris.

- Cleaving: Cutting the fiber ends at a perfect 90° angle.

- Aligning: Positioning the fiber cores precisely in a fusion splicer.

- Fusing: Applying a controlled electric arc to melt and bond the glass ends.

- Protecting: Encasing the splice in a protective sleeve to prevent mechanical damage.

Historical Background

Fusion splicing emerged in the 1970s, shortly after the development of low-loss optical fiber that made fiber-optic communication practical. Early methods used mechanical splices and epoxy-based bonding, but these were unreliable and caused excessive signal loss.

The introduction of fusion splicers in the late 1970s and 1980s marked a major technological advance, allowing technicians to create precise, durable connections in the field. Companies such as Fujikura, Sumitomo, and Corning played significant roles in commercializing splicing equipment and fiber technology.

With the expansion of telecommunications, cable TV, and later internet infrastructure, fusion splicing became a cornerstone of the fiber-optic revolution.

Industrial Importance

In the modern era, fusion splicing is indispensable across several industries:

- Telecommunications: Used to connect long-haul and metro fiber networks with minimal signal degradation.

- Data Centers: Ensures reliable internal connections between switches, servers, and backbone links.

- Energy & Utilities: Provides stable fiber links for smart grids and remote monitoring systems.

- Defense & Aerospace: Ensures ruggedized, high-precision optical systems in mission-critical environments.

- Industrial Automation: Supports factory control systems relying on fiber-based sensors and data lines.

Because of its low insertion loss, long-term reliability, and permanent nature, fusion splicing remains the gold standard for high-performance optical connections.

BitcoinVersus.Tech Editor’s Note:

We volunteer daily to ensure the credibility of the information on this platform is Verifiably True. If you would like to support to help further secure the integrity of our research initiatives, please donate here

BitcoinVersus.tech is not a financial advisor. This media platform reports on financial subjects purely for informational purposes.

Leave a comment