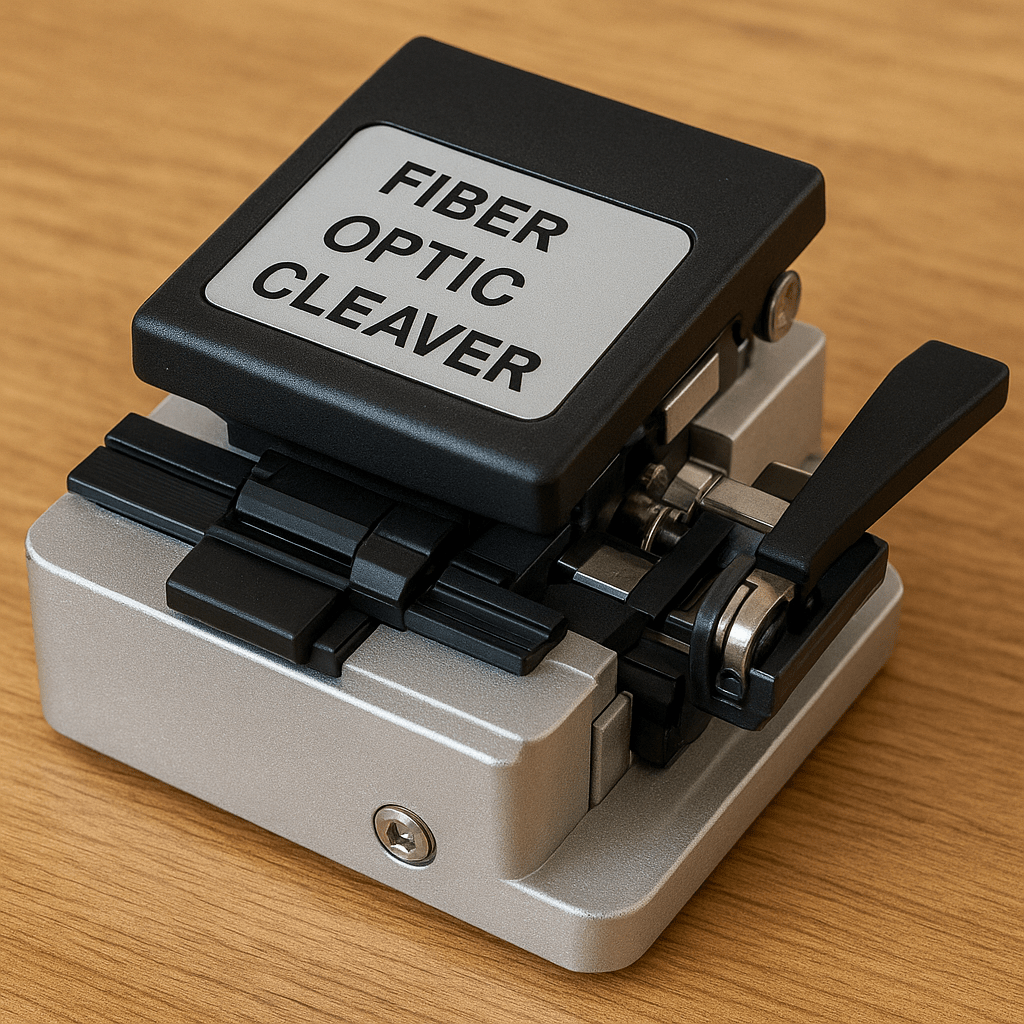

Cleaving fiber is a controlled mechanical process used to prepare optical fibers for splicing or termination by creating a clean, flat break at the end of the fiber.

The goal is to produce an end face that is perpendicular to the fiber’s axis with minimal surface defects, which is critical for achieving low insertion loss and high return loss in both fusion and mechanical splices.

The process typically involves a scribe-and-tension technique, where a small crack is introduced into the fiber using a sharp blade—commonly made of diamond, tungsten carbide, or sapphire—and then a tensile force is applied to propagate the fracture cleanly across the fiber’s cross-section. This method avoids crushing or deforming the fiber and ensures a high-quality cleave.

Cleaving is performed after stripping the fiber’s protective coating and before splicing or inserting it into a connector ferrule.

In connectorization, especially with epoxy-based terminations, cleaving ensures that the fiber end protruding from the ferrule is flush and ready for polishing. Poor cleaves can result in angled or jagged surfaces, leading to signal loss, reflection, or physical damage during mating.

BitcoinVersus.Tech Editor’s Note:

We volunteer daily to ensure the credibility of the information on this platform is Verifiably True. If you would like to support to help further secure the integrity of our research initiatives, please donate here

BitcoinVersus.tech is not a financial advisor. This media platform reports on financial subjects purely for informational purposes.

Leave a comment