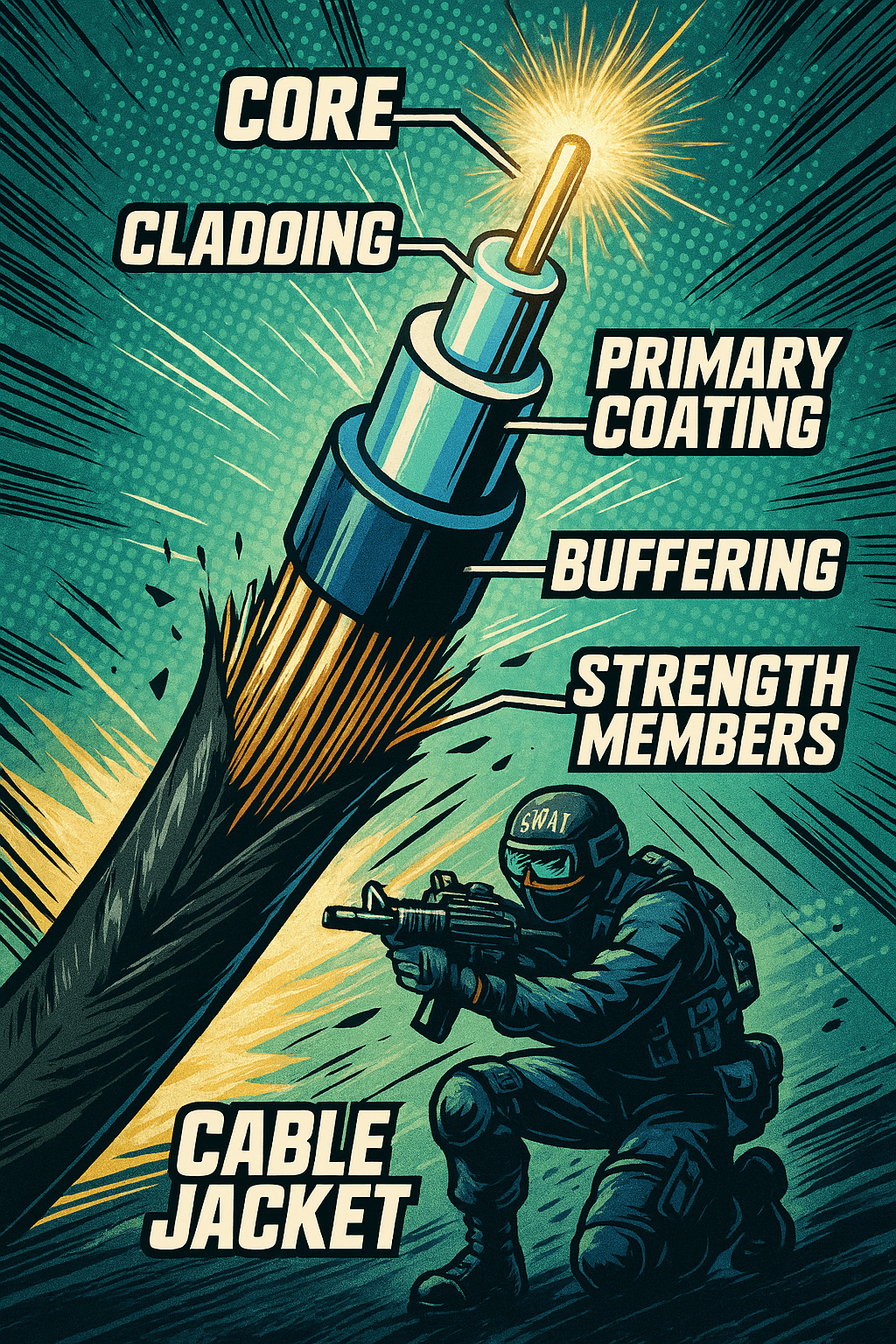

Core

The core is the central strand of a fiber optic cable, composed of ultra-pure glass or plastic. It serves as the transmission medium for light signals. The diameter of the core depends on the fiber type—typically 9 microns for single-mode fibers and 50 or 62.5 microns for multimode. Its refractive index is slightly higher than the surrounding cladding, allowing light to be guided through the fiber via total internal reflection.

Cladding

Surrounding the core is the cladding, a concentric layer also made of silica but engineered with a slightly lower refractive index. This differential ensures that light signals remain confined within the core, bouncing internally without escaping. The cladding maintains a standard diameter of 125 microns and is essential for preserving signal integrity and minimizing loss over long distances.

Primary Coating

The primary coating is a dual-layer acrylate polymer applied directly to the cladding during manufacturing. Its inner layer is soft to cushion the fiber, while the outer layer is harder to resist mechanical stress. This coating protects the glass from microbending, moisture, and physical damage, and brings the total diameter of the fiber to approximately 250 microns. It is stripped away during splicing or connectorization.

Buffering

Buffering refers to the protective layer added over the primary coating. It comes in two main forms: tight buffer and loose buffer. A tight buffer is a 900-micron polymer jacket bonded directly to the coating, commonly used in indoor cables for flexibility and ease of termination. A loose buffer consists of a plastic tube that loosely houses one or more fibers, allowing for movement and thermal expansion—ideal for outdoor environments where mechanical stress and temperature variation are more pronounced.

Strength Members

Strength members are materials embedded within the cable to provide tensile reinforcement and prevent strain on the optical fibers. These can include aramid yarn (such as Kevlar), fiberglass rods, or steel wires. Their primary function is to absorb mechanical stress during pulling, installation, and environmental shifts, ensuring the fibers remain undamaged and signal transmission remains stable.

Cable Jacket

The cable jacket, also known as the outer sheath, is the final protective layer of the fiber optic cable. It is made from materials such as PVC, LSZH (low smoke zero halogen), or polyethylene, depending on the installation environment. The jacket shields the cable from abrasion, chemicals, UV radiation, and flame. It also follows industry color conventions to indicate fiber type—yellow for single-mode, orange or aqua for multimode.

Optional Layers

Some fiber optic cables include additional layers for enhanced protection and functionality. Water-blocking gel or tape may be added to prevent moisture ingress in outdoor cables. Ripcords, which are nylon threads placed beneath the jacket, facilitate easy removal of the outer sheath. In rugged environments, metallic armor such as corrugated steel or aluminum may be included to protect against rodent damage and crushing forces.

BitcoinVersus.Tech Editor’s Note:

We volunteer daily to ensure the credibility of the information on this platform is Verifiably True. If you would like to support to help further secure the integrity of our research initiatives, please donate here

BitcoinVersus.tech is not a financial advisor. This media platform reports on financial subjects purely for informational purposes.

Leave a comment