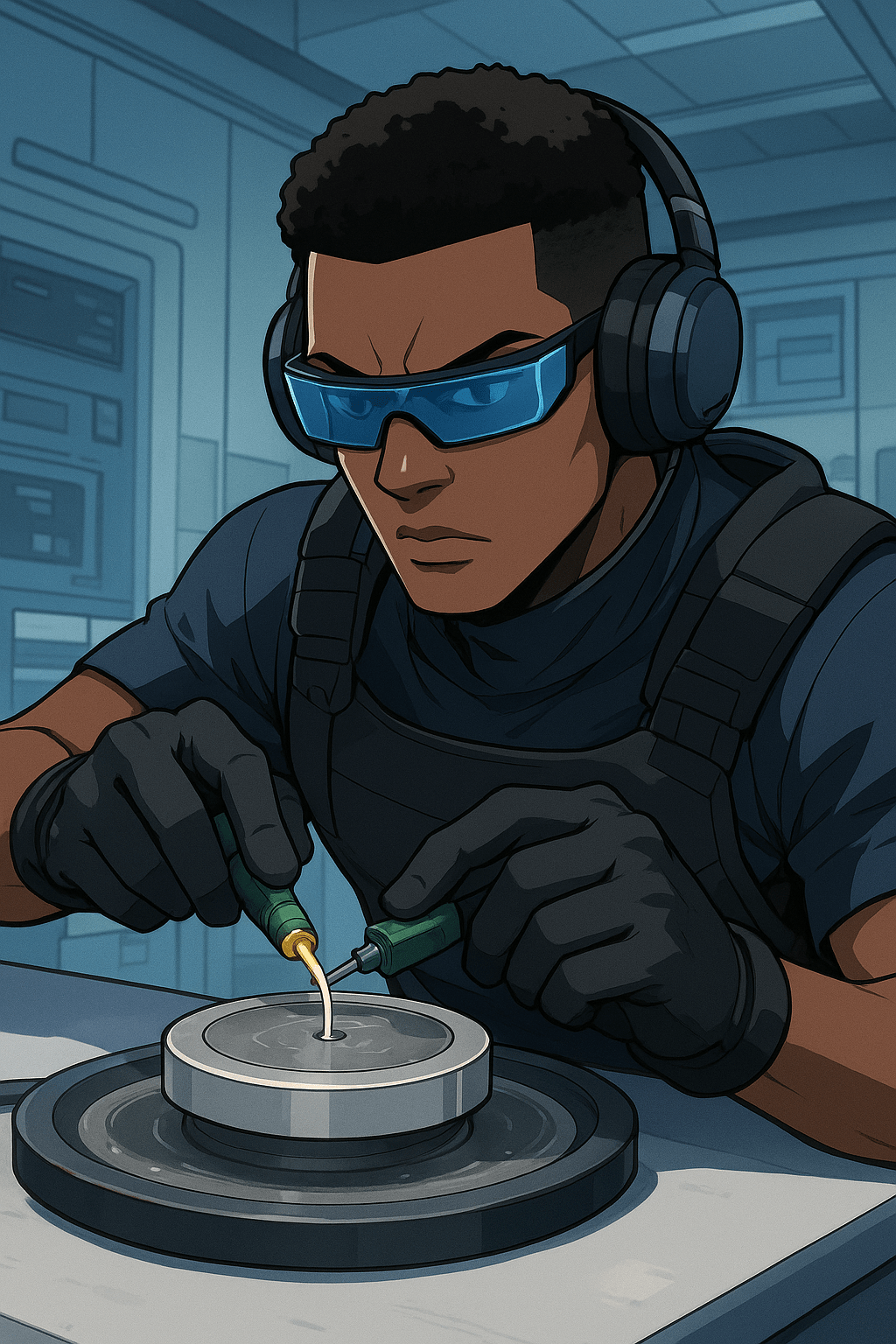

Polishing fiber is the final stage in preparing an optical fiber connector, ensuring a smooth, scratch-free end face that allows for minimal signal loss and optimal light transmission.

The procedure begins after the fiber has been cleaved and secured in a connector ferrule using epoxy or a mechanical fit.

Once the adhesive cures, the protruding fiber tip is carefully trimmed and polished to achieve a mirror-like surface.

Technicians typically use a fiber polishing machine or a hand polishing puck along with polishing films of varying grit sizes, starting with coarse (typically 12 μm) and progressing to ultra-fine (0.3 μm or finer) diamond lapping films.

The process is performed on a flat glass polishing plate, often covered with a rubber pad to maintain even pressure.

A polishing fixture holds the connector at a precise angle—usually 0° for flat polish or 8° for angled physical contact (APC) connectors. Deionized water or alcohol may be applied to the polishing surface to reduce friction and remove debris.

Once polishing is complete, the connector end face is inspected under a fiber microscope or interferometer to verify that the surface meets industry standards for geometry and cleanliness.

BitcoinVersus.Tech Editor’s Note:

We volunteer daily to ensure the credibility of the information on this platform is Verifiably True. If you would like to support to help further secure the integrity of our research initiatives, please donate here

BitcoinVersus.tech is not a financial advisor. This media platform reports on financial subjects purely for informational purposes.

Leave a comment