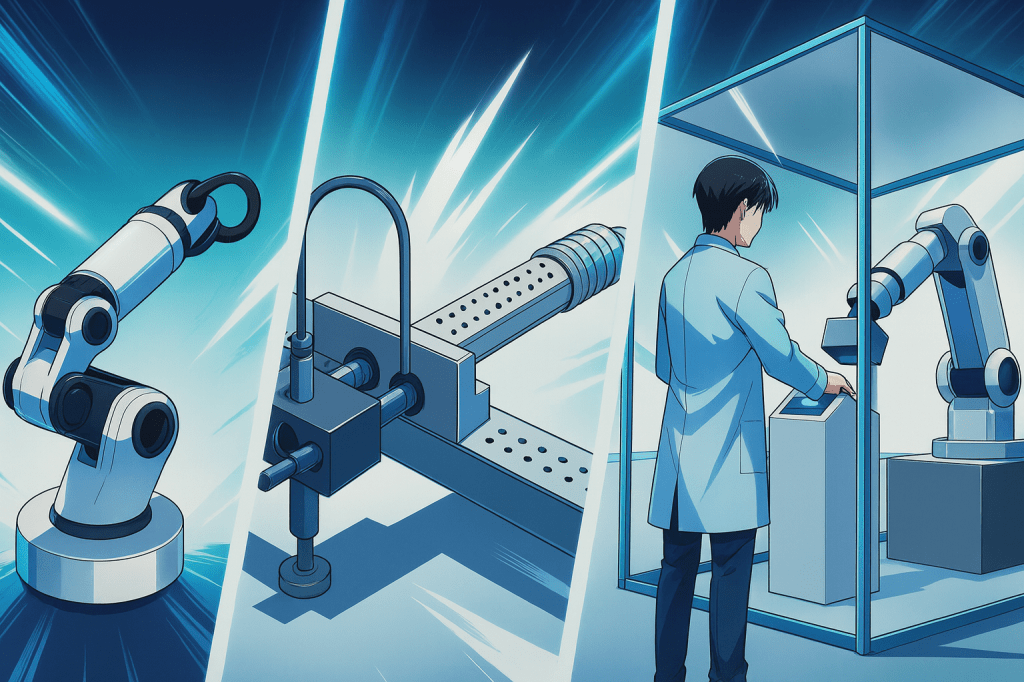

Industrial robots are highly versatile automation systems designed for a wide range of tasks in manufacturing and production environments.

They are freely programmable, meaning their operations can be customized and reconfigured for different applications. These robots are also freely positionable, allowing them to be installed in various locations within a facility. Their universal applicability makes them suitable for tasks such as welding, painting, assembly, and material handling, often featuring multi-jointed arms that mimic human motion for precision and flexibility.

Insertion devices are specialized machines used primarily for repetitive, point-to-point operations such as feeding components into a system or placing items in precise locations. Unlike industrial robots, insertion devices operate on a fixed program, meaning their actions are predetermined and not easily reconfigurable. They are ideal for high-speed, consistent tasks where variability is minimal, such as inserting electronic components onto circuit boards or packaging items in assembly lines.

Manipulators are manually controlled devices designed to handle tasks that involve either extremely heavy loads, extremely small objects, or operations in hazardous environments.

These systems are operated by human workers, often through remote control or mechanical linkages, allowing for safe interaction with dangerous materials or delicate components. Manipulators are commonly used in industries like nuclear energy, pharmaceuticals, and aerospace, where precision and safety are paramount, and human dexterity is needed without direct exposure to risk.

BitcoinVersus.Tech Editor’s Note:

We volunteer daily to ensure the credibility of the information on this platform is Verifiably True. If you would like to support to help further secure the integrity of our research initiatives, please donate here

BitcoinVersus.tech is not a financial advisor. This media platform reports on financial subjects purely for informational purposes.

Leave a comment