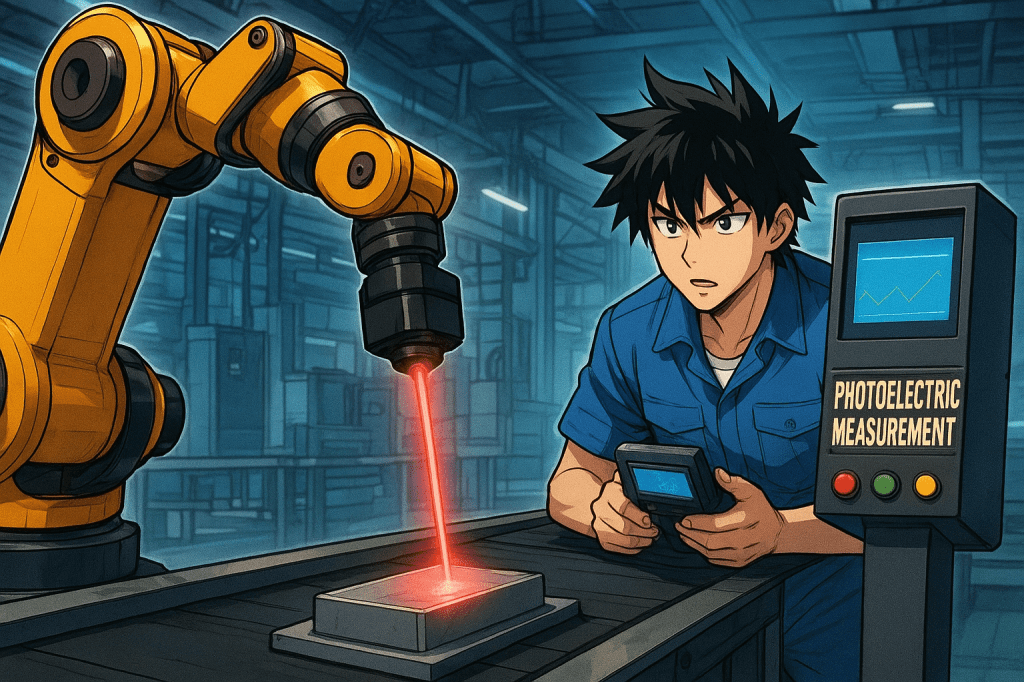

Photoelectric measurement in industrial robotics is a high-precision sensing technique that relies on the detection of light to determine the position, movement, or presence of objects within an automated system.

It typically involves a light source, optics, a scanning grid, and a photoelectric sensor that responds to changes in illumination caused by transitions between light and dark elements on a measuring standard.

As a robot moves across this patterned surface, the sensor detects these transitions and converts them into electrical signals, which are then interpreted to calculate the robot’s exact position along an axis.

This method is non-contact, which minimizes mechanical wear and enhances system longevity, and it offers micron-level accuracy, making it ideal for high-speed industrial environments such as semiconductor fabrication, CNC machining, and automated assembly lines.

By enabling real-time feedback and precise control, photoelectric measurement plays a critical role in improving the efficiency, repeatability, and safety of robotic operations in modern manufacturing.

BitcoinVersus.Tech Editor’s Note:

We volunteer daily to ensure the credibility of the information on this platform is Verifiably True. If you would like to support to help further secure the integrity of our research initiatives, please donate here

BitcoinVersus.tech is not a financial advisor. This media platform reports on financial subjects purely for informational purposes.

Leave a comment